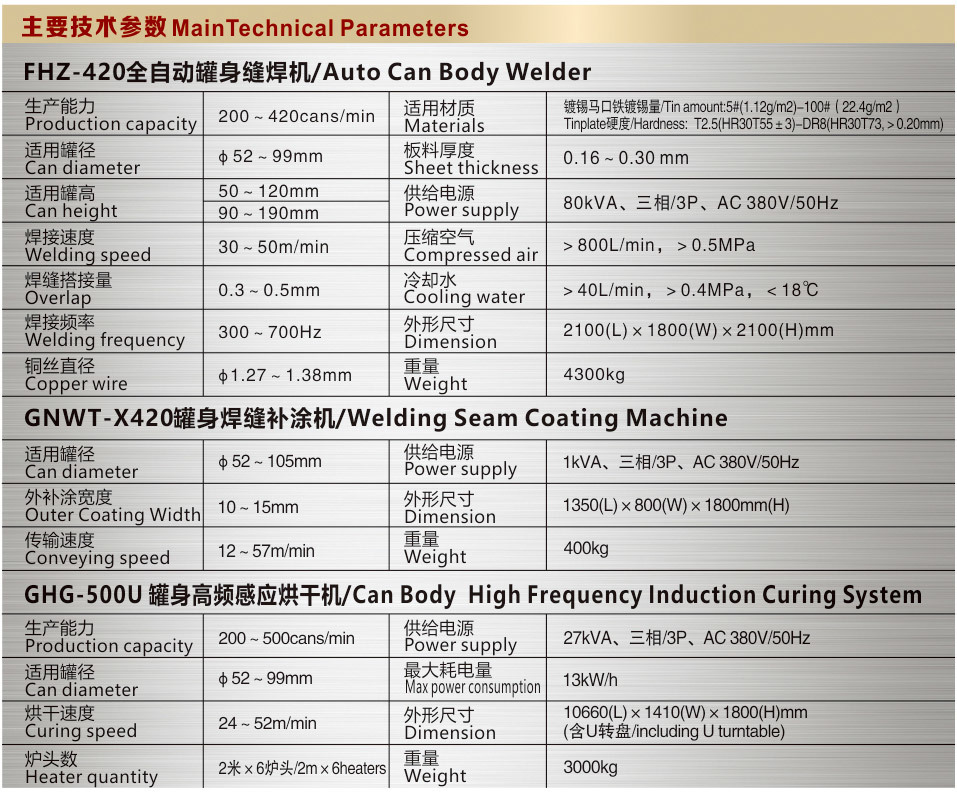

FHZ-420 Auto Can Body Production Line

This production line applies to auto welding, coating and curing of food and beverage cans with a production capacity of 420 cans/min.

Lifetime customer support!

- Quality Guaranteed

- Fast Shipping

- Secure Payments

Description

Advantages

- Apply to a vast variety of cans. One machine for multiple purposes.

- Utilize double crank suction feeder and can pushing fork, one by one magnetic separation to eliminate plate scratch and ensure stable feeding.

- The roling machine is equipped with automatic lubricating system so the rlling machine doesn’t need to be stopped to do lubricating. Multiple rounds of kneading and forming to ensure stable rounding. Double sheet detection with auto elimination for non-stop production.

- Adopt ZrO2 for key parts like Z-shaped guide way and sizing gauge bearing to make them toughen,which is non-cooling and wear-resisting and has a longer service life. With new variable frequency inverted welding technology to make a perfect welding seam.

- Adopt four-bar mechanism with large-bore cylinder to ensure stable lifting and accurate transition position of can catching.

- With high frequency induction curing system, it saves more than 80% energy compared to traditional ones;Venting and exhausting system is adopted to comply with requirement for environment protection and optimize production environment.

- Servo control system and frequency control are adopted to ensure accurate control.

- Man-machine interface is in English & Chinese and every module parameter is stored to facilitate easy operation. There is also auto-diagnosis function to ensure safety.

*Remark: Equip a marker will help enhance production capacity 1 time for cans with height of 25~ 80mm because the marked can will be cut into two in the end.

Reviews

There are no reviews yet.