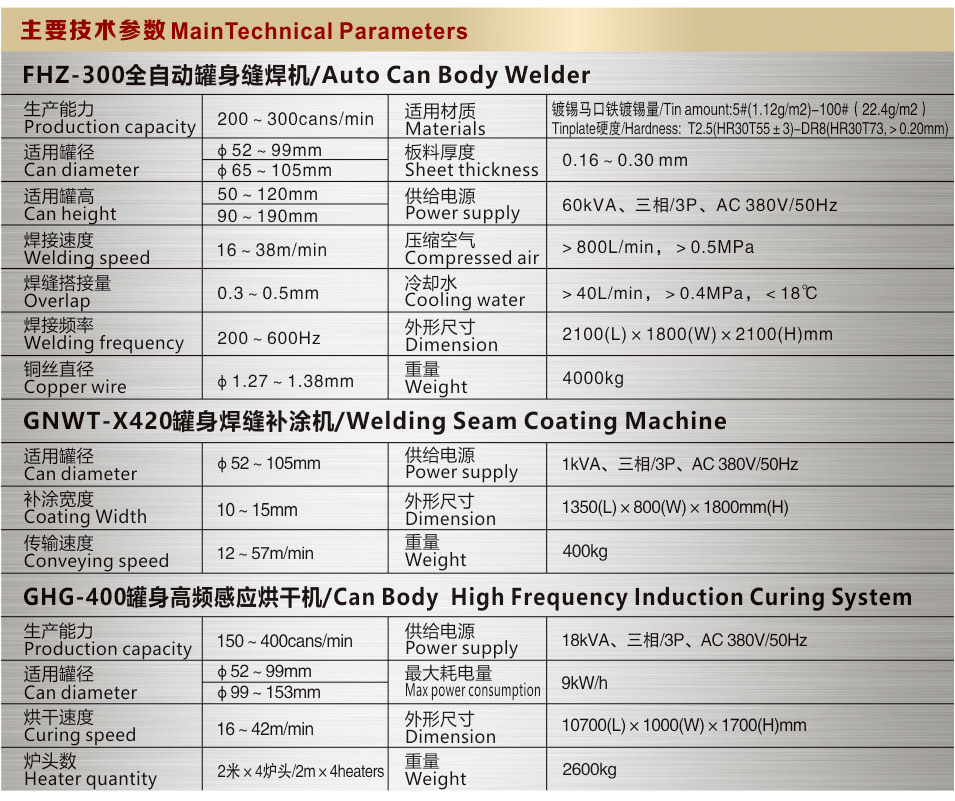

FHZ-300 Auto Can Body Production Line

This production line applies to auto welding, coating and curing of food and beverage cans with a production capacity of 300cans/min.

Lifetime customer support!

- Quality Guaranteed

- Fast Shipping

- Secure Payments

Description

Advantages

- Utilize double crank suction feeder and can pushing fork to have more stable feeding and adopt magnetic separation to avoid tin plate scratch.

- The rlling machine is equipped with automatic regular lubricating system in a fixed quantity so the rolling machine doesn’t need to be stopped to do lubricating. This will lead to less maintenance work and lengthen service life.

- Equipped imported needle roller bearing, rolling machine is designed as foolproof module.

- Adopt new technique and craft for key parts, durable and tin adhension is avoided accordingly.

- Adopt cermet for key parts which is insulating and wear-resisting and has a longer service life. With new variable frequency inverted welding technology to make a perfect welding seam.

- Equipped with copper wire cooling device to ensure stable elongation so that same gaps between cans and great welding quality of front & back ends of welding seam is achieved.

- Adopt servo control system and frequency control to ensure accurate control.

- Double-sheet detection with auto elimination for non-stop production.

- Man-machine interface is in English & Chinese and every module parameter is stored to facilitate easy operation. There is also auto-diagnosis function and reserved remote communication port to achieve convenient point-to-point service.

- Protection cover and safety electric door locker are added as standard to ensure safety.

Reviews

There are no reviews yet.