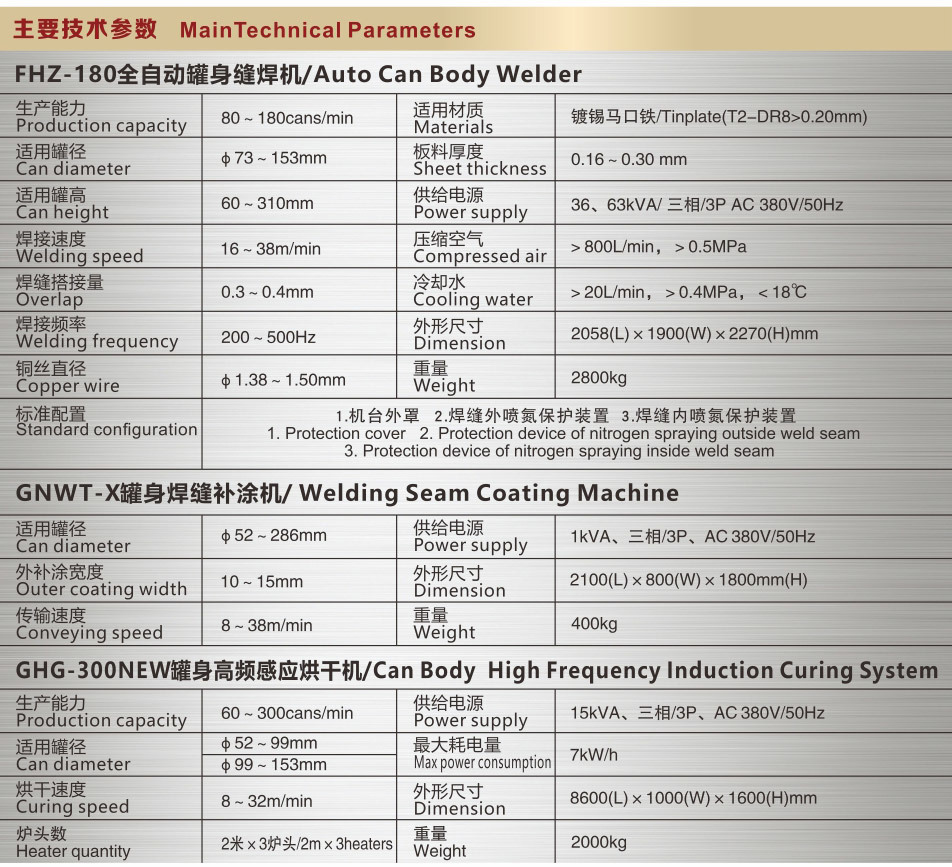

FHZ-180 Auto Can Body Production Line

This seam welding machine applies to the auto welding of food, milk cans with diameter of Φ 73~153mm and height of 60~310mm.

Lifetime customer support!

- Quality Guaranteed

- Fast Shipping

- Secure Payments

Description

Advantages

- Adopt cermet for key parts like fatten roller,Z-shaped guideway and sizing gauge bearing,which is non-cooling and wear-resisting and has a longer service life.

- Adopt double cranks for suction feeder and can pushing system to ensure stable can pushing and easy adjusting.

- Adopt two SMC rodless cylinder tensioning for copper wire system to ensure more stable running,

- Adopt aluminum allay of high intensity for can rounding and protection device to avoid power consumption caused by heating.

- With new variable frequency inverted welding technology to make a perfect welding seam.

- Adopt four- bar mechanism with large-bore cylinder to ensure stable lifting and accurate transition position of can catching.

- With high frequency induction curing system, it saves more than 80% energy compared to traditional ones;Venting and exhausting system is adopted to comply with requirement for environment protection and optimize production environment.

- System is stable and reliable thanks to the electrics with international renown brands such as Schneider, Mitsubishi, Omron,SMC, etc.

- Man-machine interface is in English & Chinese and every module parameter is stored to facilitate easy operation. There is also auto-diagnosis function for safety.

- Protection cover and safety electric door locker are added as standard to ensure safety.

Reviews

There are no reviews yet.